Dyestuff industry experts

ITMA AISA 2024

- Home

- About

- Online Q & A

- Products

- Applications

- Solution

- Service

- Our Brand

- Info

- Contact

Views: 24 Author: Site Editor Publish Time: 2025-04-30 Origin: Site

In the field of dyeing polyester textiles, disperse dyes are irreplaceable core materials. In recent years, with the tightening of environmental protection regulations and the popularization of intelligent manufacturing technology, liquid disperse dyes have gradually emerged and formed differentiated competition with traditional powdered disperse dyes. This article deeply analyzes the differences and applicable scenarios between the two from the dimensions of technical characteristics, production applications, cost-effectiveness and industry trends.

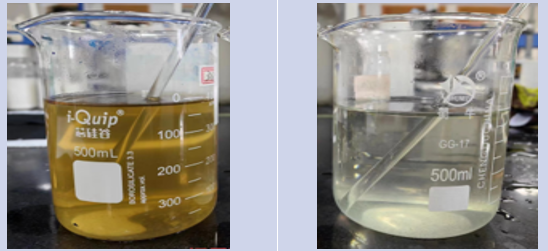

Liquid disperse dyes exist in the form of liquid suspensions, usually with water or organic solvents as carriers. The dye particles are evenly dispersed to less than 1 micron through high-pressure homogenization or nano-grinding technology to form a "ready-to-use" pre-dispersed system. Its ingredients not only include the main dye, but also pre-mixed functional additives such as dispersants and stabilizers, which can be directly put into the dyeing process to avoid the tedious steps of on-site dispersion. However, the storage conditions of liquid dyes are relatively harsh, requiring strict antifreeze and light protection, and the shelf life is usually no more than 12 months.

Ordinary disperse dyes exist in the form of powder or granular solids, with a particle size distribution between 1 and 5 microns. When used, dispersants need to be added manually or mechanically, and the dye solution needs to be homogenized by stirring, ultrasound, etc. Although its composition is relatively simple (mostly pure dyes or containing a small amount of dispersants), its storage stability is significantly better than that of liquid dyes. It can be stored for 2 to 3 years under moisture-proof conditions, and is more suitable for production scenarios with a long supply chain.

The production process of liquid disperse dyes greatly simplifies the traditional process: after the dye is synthesized, a suspension is directly formed by wet grinding, eliminating high-energy consumption links such as spray drying and granulation. It is estimated that its production energy consumption can be reduced by more than 40% compared with powdered dyes, and carbon emissions can be reduced by about 30%. However, liquid dyes require the addition of a large amount of auxiliaries to maintain the stability of the system, which leads to an increase in the chemical oxygen demand (COD) of dyeing wastewater and an increase in treatment costs. In addition, liquid packaging mostly uses plastic barrels, and the recycling of discarded packaging also needs to be included in environmental protection considerations.

Ordinary disperse dyes rely on traditional spray drying processes to convert dye solutions into powders or granules. This process not only consumes a lot of heat energy (accounting for 30%~50% of the total cost), but also produces dust pollution, and dust removal equipment is required to meet occupational health standards. However, the content of additives in the dyeing wastewater is low, the treatment difficulty is relatively small, and solid packaging (such as woven bags) is easier to recycle.

In terms of dyeing effect, the pre-dispersion characteristics of liquid disperse dyes show significant advantages. Its ultrafine particles can quickly penetrate complex fabrics such as ultrafine denier fibers and high-density polyester, improve dyeing uniformity by 15%~20%, and control color difference within 5%, which is particularly suitable for sportswear, high-end home textiles and other fields with strict quality requirements. In addition, liquid dyes can be directly connected to the automated feeding system, greatly improving the efficiency of continuous pad dyeing and roll dyeing production lines, and reducing manual intervention by more than 50%.

Although ordinary disperse dyes have the risk of color flower caused by uneven dispersion, their cost advantage is particularly prominent in small batch and multi-variety orders. For example, when printing, printing factories can flexibly control the color light by adjusting the type of dispersant during proofing, and the cost of a single batch can be 30% to 40% lower than that of liquid dyes. At the same time, powdered dyes are stable in high-temperature and high-pressure dyeing processes and are still the first choice for traditional immersion dyeing vat processes.

From the perspective of direct cost, the unit price of liquid disperse dyes is usually more than 50% higher than that of ordinary dyes, but its comprehensive cost is more competitive in large-scale production. Taking a polyester dyeing workshop with an annual output of 10,000 tons as an example, liquid dyes can save about 250,000 yuan/year in energy consumption in the dispersion process, reduce dye waste by about 8%, and reduce labor costs by 15% with automated equipment. For small and medium-sized dyeing factories, ordinary dyes have lower initial investment and do not need to transform existing equipment and storage systems, so the short-term economic benefits are more significant.

Environmental protection policies are also reshaping the market structure. The strict restrictions on dust pollution by the EU REACH regulations have enabled liquid dyes to exceed 45% of the European market share; while in cost-sensitive regions such as India and Southeast Asia, ordinary dyes still occupy more than 70% of the market share.

V. Future Trends and Innovation Directions

The industry consensus is that liquid disperse dyes will gradually upgrade to functional and green:

Low-temperature dyeing technology: Develop liquid dyes that can be dyed at 80°C, suitable for polyester/spandex blended fabrics, and reduce energy consumption by 40%;

Bio-based additives: Use natural materials such as lignin and chitosan to replace petroleum-based dispersants to reduce chemical pollution to water bodies;

Recycling model: Recover dyes from wastewater through membrane separation technology, with a reuse rate of up to 35%, promoting "zero-emission" dyeing.

Ordinary disperse dyes have not stagnated. Nano-coating technology allows their particle size to be controlled within 0.5 microns, and some performance is close to that of liquid dyes. In the future, the two may move towards a "hybrid mode" - powdered dyes are quickly dispersed through ready-to-use additive packages, taking into account both cost and efficiency.

content is empty!