Dyestuff industry experts

ITMA AISA 2024

- Home

- About

- Online Q & A

- Products

- Applications

- Solution

- Service

- Our Brand

- Info

- Contact

Views: 67 Author: Emily Publish Time: 2025-02-06 Origin: Site

The process of printing with acid dyes on nylon fabric is a specialized technique that requires careful attention to the fabric's properties and the dye's characteristics. This document outlines the steps involved in the printing process, from fabric preparation to final fixation, ensuring vibrant and durable prints.

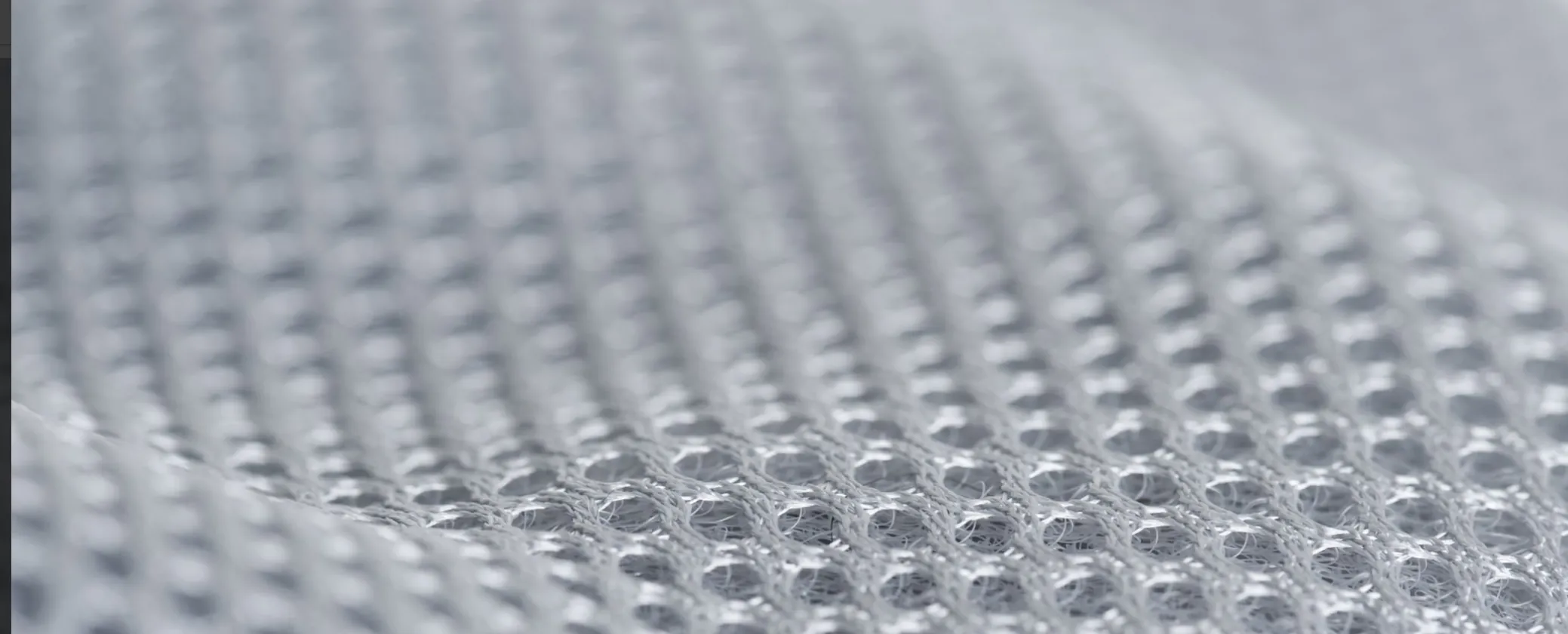

Nylon, a synthetic fabric known for its strength and elasticity, is often used in the production of various textiles, including sportswear, lingerie, and outdoor gear. Acid dyes are particularly suitable for nylon due to their affinity for synthetic fibers. This guide will walk you through the essential steps of the nylon acid dye printing process.

1. Scouring: Begin by scouring the nylon fabric to remove any oils, dirt, or finishes that could interfere with the dye's ability to penetrate the fibers. Use a mild detergent and warm water, agitating the fabric gently for about 30 minutes.

2. Rinsing: After scouring, rinse the fabric thoroughly with clean water to remove any soap residue.

3. Drying: Allow the fabric to air dry completely before proceeding to the printing process.

Printing Preparation:

1. Design Creation: Develop your design using graphic design software. Ensure that the design is suitable for the printing method you will be using, such as screen printing or digital printing.

2. Screen Preparation: For screen printing, create a stencil of the design on a fine mesh screen. For digital printing, prepare the digital file for printing.

1. Mixing the Dye: Mix the acid dye with a urea solution to enhance the dye's affinity for the nylon fabric. The ratio of dye to urea solution will depend on the desired intensity of the color.

2. Printing: Apply the dye mixture onto the fabric using the chosen printing method. For screen printing, use a squeegee to push the dye through the stencil. For digital printing, follow the printer's instructions for printing on nylon.

3. Drying: Allow the printed fabric to dry at room temperature. Avoid direct heat sources that could set the dye prematurely.

1. Steaming: After the fabric is dry, it needs to be steamed to set the dye. Use a steamer or an oven set to steam mode, and expose the fabric to steam for 15-20 minutes.

2. Washing: Once steamed, rinse the fabric in warm water to remove any excess dye. Use a mild detergent if necessary.

3. Drying: Finally, air dry the fabric or tumble dry on a low heat setting.

1. Inspection: Inspect the printed fabric for any imperfections or color variations.

2. Heat Setting: To ensure the print's durability, heat set the fabric using an iron or a heat press. Follow the recommended temperature for nylon, which is typically around 280°F (138°C).

3. Final Inspection: Perform a final inspection to ensure the print meets quality standards.

The nylon acid dye printing process requires precision and attention to detail to achieve high-quality results. By following these steps, you can create beautiful, long-lasting prints on nylon fabric. Always remember to test your process and materials before starting a large-scale production to avoid any unwanted surprises.

If you want to know more about dyeing solutions, please contact: info@tiankunchemical.com