Dyestuff industry experts

ITMA AISA 2024

- Home

- About

- Online Q & A

- Products

- Applications

- Solution

- Service

- Our Brand

- Info

- Contact

Views: 1 Author: Site Editor Publish Time: 2026-02-14 Origin: Site

You can get the best disperse dyes for digital printing from brands like Tiankun Chemical. The table below lists top products. These products give bright colors and last a long time:

Brand | Product Name | Description |

|---|---|---|

Tiankun Chemical | Disperse TXF Series | These textile inks have great color and stay bright for a long time. |

Tiankun Chemical | Skycron Disperse Dyes | These dyes are used for polyester fabrics. They give strong and lasting color. |

You will see color strength gets better as you use more dye. A pH of 7 helps colors look brighter. Disperse Yellow dye gives stronger color than Disperse Red dye if you use the same amount. Both K/S and ∆E values show great results even at just 1% dye concentration.

Pick disperse dyes from trusted brands like Tiankun Chemical. These dyes make prints bright and last a long time.

Use fabrics with at least 65% polyester. This helps your designs look sharp and colorful.

Make sure your dyes have strong fastness properties. This keeps colors after washing, light, and rubbing.

Check if your printer works well with the dyes. Use dyes that flow easily and do not clog print heads.

Choose eco-friendly disperse dyes. This helps reduce waste and protects the environment. You still get great results.

Test dye and fabric combinations before big projects. This makes sure you get good transfer and print quality.

Think about the total cost, including dye quality and print life. This can help you save money over time.

Follow quality tips, like using the right heat press and settings. This helps you get prints that are always bright and clear.

You want your prints to be bright and bold. Color vibrancy depends on disperse dyes and the fabric you use. Polyester fabrics work best because they bond well with sublimation inks. If your fabric has at least 65% polyester, your prints will look more vivid. The weave or knit of the fabric matters too. Tightly woven fabrics absorb ink better and make images sharper. Smooth surfaces help colors look clear and true. Light-colored fabrics show the real shades because sublimation inks are see-through.

Tip: Pick fabrics that are smooth and have lots of polyester for the brightest prints.

Here is a quick look at what affects color vibrancy:

Factor | Description |

|---|---|

Fiber Composition | Polyester or polymers are best. At least 65% polyester makes prints vibrant. |

Fabric Weave or Knit | Tight weaves or knits give sharper, more detailed prints. |

Surface Finish & Color | Smooth, light surfaces help show true colors. |

Fastness means how well the color stays on the fabric after washing, light, or rubbing. You need disperse dyes with strong fastness so your prints last longer.

Wash fastness shows how well the color stays after washing many times. You want prints that do not fade or bleed. Good disperse dyes keep colors bright after lots of washes. Polyester fabrics help the dye stay in place.

Light fastness shows how well the color resists fading from sunlight or indoor lights. If you print banners or sportswear, you need dyes that can handle light. Good disperse dyes protect your prints from fading and keep them looking fresh.

Rubbing fastness checks if the color rubs off when you touch or handle the fabric. You want prints that stay clean and do not transfer color to other things. Strong rubbing fastness means your prints will look good even after lots of use.

Here are some things that affect fastness:

Factor | Description |

|---|---|

Pressure | Even contact during testing gives accurate results. |

Fabric Properties | Different fabrics and thickness change heat transfer and staining. |

Certification | Multi-fiber lining is now used for testing fastness. |

Transfer efficiency tells you how well the dye moves from paper to fabric during sublimation. You want most of the dye to transfer so your prints look bright and clear. High transfer efficiency means less waste and better results. The right disperse dyes help you get strong color and sharp images. You get consistent prints when the dye transfers smoothly and evenly.

Note: Always check that your dye and fabric match for the best transfer efficiency.

You have to check if your disperse dyes work with your printer. Printer compatibility is very important for good sublimation printing. Most digital printers use inkjet technology. These printers need dyes that flow easily. The dyes should not block the print heads. You want dyes that spread evenly in the ink. They must stay stable while printing.

Disperse dyes are made for polyester fibers. Their small molecules move into the fabric when heat is used. This helps you get prints that are bright and strong. You must make sure your dye fits your printer model. Some printers need special ink formulas. Always read the printer’s manual or ask your supplier for help.

Here are things to think about for printer compatibility:

Ink Formulation: Pick dyes that mix well with your ink base. This stops clogging and keeps your printer working.

Particle Size: Small particles let the dye go through the print head easily. You get clear and sharp images.

Printer Model: Some printers need special dyes. Make sure your dye works for your printer.

Temperature Settings: Sublimation printers use high heat. Your dye must handle this heat without breaking.

Tip: Try your dye with your printer before you start a big job. This helps you avoid problems and get the best prints.

Check the table below to see what you need for printer compatibility:

Printer Type | Dye Requirement | Benefit |

|---|---|---|

Inkjet Sublimation | Small particle size, stable ink | Sharp images, smooth operation |

Large Format | High dispersion, heat resistance | Bright colors, fast printing |

Desktop | Easy mixing, low clog risk | Reliable prints, easy maintenance |

You should think about the environment when picking disperse dyes for sublimation printing. Many companies want eco-friendly choices now. Disperse dyes can help cut waste because they transfer almost all color from paper to fabric. This means less leftover dye and less pollution.

Some dyes use safer chemicals. These dyes do not hurt water or air. You can look for products with certifications like OEKO-TEX or GOTS. These labels show the dyes meet strict safety rules. Using eco-friendly dyes helps protect the planet and keeps your workplace safe.

Here are ways to lower your environmental impact:

Pick dyes with high transfer efficiency. You waste less ink and get better prints.

Choose dyes with safe ingredients. This keeps your water clean and your air fresh.

Use printers that save energy. This lowers your power use and helps the environment.

Note: Always ask your supplier about the environmental standards of their dyes. This helps you make smart and responsible choices.

You can help by picking the right disperse dyes. Eco-friendly options give you great results and help build a better future.

It is important to pick the right disperse dyes for sublimation digital printing. The best dyes give you bright colors and strong prints. They also help your prints last a long time. Let’s see which types and brands are the best.

High-energy disperse dyes stick to polyester at a tiny level. This makes your prints bright and tough. Your images look smooth and do not crack or peel. These dyes also keep their color in sunlight. They work well for direct digital printing on polyester.

Here is a table that shows the main types of disperse dye inks:

Type of Disperse Dye Ink | Characteristics |

|---|---|

Low-energy Disperse Dye Ink | Used for transfer printing; evaporates and turns to gas when heated. |

High-energy Disperse Dye Ink | Suitable for direct digital printing; offers resistance to transference, high light fastness, and stable color development. |

You can pick low-energy, medium-energy, or high-energy disperse dyes. High-energy dyes are best for digital printing on polyester.

TIANKUN CHEM is a trusted brand for disperse dyes. Their Skyinktex® Disperse Dyes for Sublimation Inks give great results. These dyes are made for digital and sublimation printing. You get strong color, bright prints, and smooth use.

Skyinktex® Disperse Dyes have many good features:

Strong color and good results

Good for dyeing polyester fabrics

Bright colors that last a long time

Can be used for different printing methods

Colors stay bright after many washes

Low water solubility and good heat resistance

You can see how TIANKUN CHEM dyes perform in this table:

Product Name | Performance Characteristics |

|---|---|

Skycron Yellow TXF | High color fastness |

Skycron Golden Yellow TXF | High brightness |

Skycron Brown TXF | Excellent levelness |

Skycron Rubine TXF | Suitable for polyester applications |

Skycron Red 3BS TXF | High-performance dye |

Skycron Rubine 4BS TXF | Good all-round color fastness |

Skycron Scarlet TXF | High productivity in dyeing |

Skycron Turq.Blue TXF | Optimized rapid dyeing |

Skycron Blue 2GS TXF | Excellent build-up properties |

Skycron Navy Blue TXF | Suitable for difficult fabrics |

Skycron Black HWT TXF | Economical dye recipes |

Skycron Navy Blue GS TXF | High accuracy in standardizing shades |

Tip: You can use Skyinktex® Disperse Dyes for flags, banners, sportswear, and fashion fabrics. These dyes give you vivid colors and reliable performance.

Skyinktex® Disperse Dyes come in many colors. Some choices are Blue 56, Fluo. Red 364, Fluo. Yellow 82, Brown 27, Orange 25, Blue 360, Blue 359, Blue 72, Blue 14, Red 60, and Yellow 54. You can pick colors that fit your design.

You can use these dyes for:

Textile printing

Sportswear

Flags and banners

Fashion fabrics

Advertising materials

Skyinktex® Disperse Dyes work well with digital printers. You get sharp images and even color. The colors stay bright after washing and sunlight.

There are other brands with good disperse dyes for sublimation printing. Here is a table with some commercial names and makers:

Commercial Name | Manufacturer |

|---|---|

Dispersol | BASF, Atic |

Cibaset | CIBA |

Foron | Clariant |

Resolin | Dystar |

You can also see the main commercial names and types here:

Commercial Name | Type of Dye |

|---|---|

Terasil | Disperse Dye |

Foron | Disperse Dye |

Palanil | Disperse Dye |

Resolin | Disperse Dye |

Samaron | Disperse Dye |

Dispersol | Disperse Dye |

Many brands have low-energy, medium-energy, and high-energy disperse dyes. You can pick the type that works for your printing.

Note: People say that dyes like Disperse Yellow SF-6G 200% and Turquoise Blue HSF have great lightfastness and color. You can trust these dyes for outdoor fabrics and dark prints. Fluorescent disperse dyes also give bright colors and strong effects.

You can choose disperse dyes from TIANKUN CHEM or other top brands. Make sure your dye matches your fabric and printing method. You get the best results with good dyes and printers.

Disperse dyes work best on polyester fabric. Polyester holds the dye deep inside the fibers. This keeps prints bright and strong for a long time. The colors do not fade after many washes or sunlight. Different dyes have different fastness levels. Monomeric dyes are good for rubbing and washing. Polymeric dyes are best for all fastness needs. Commercial dyes are okay but not as strong. You can see how each dye type performs in the table below:

Dye Type | Rubbing Fastness | Hot Pressing Fastness | Washing Fastness | Light Fastness |

|---|---|---|---|---|

Monomeric Dyes | 4-5 | Good to Excellent | Good to Excellent | Moderate to Outstanding |

Polymeric Dyes | Excellent | Excellent | Excellent | Excellent |

Commercial Dyes | 3-4 | Good | Good | Moderate |

Tip: Pick polymeric dyes for sportswear or outdoor fabrics. They last the longest.

Disperse dyes can be used with many printing methods. You can use them for screen, digital, or transfer printing. This gives you lots of choices for your projects. Screen printing is good for big jobs and lets you control the dye paste. Digital printing is fast and gives you detailed designs. Transfer printing uses heat and pressure for complex patterns. The table below shows how each method works with disperse dyes:

Printing Technique | Compatibility with Disperse Dyes | Description |

|---|---|---|

Screen Printing | High | Uses a stencil and dye paste for big jobs and good control. |

Digital Printing | High | Made for inkjet printers, gives detailed and quick designs. |

Transfer Printing | High | Prints on paper, then uses heat to move the design to fabric. |

Note: You can change printing methods and still keep good color and fastness.

Dye sublimation on polyester has many benefits. Your prints look bright and clear. The colors last a long time and do not rub off. The dye bonds with the fabric, so designs stay strong after washing. Colors stay stable and bright. There are some limits too. Sometimes, the dye can move inside the fabric. Pressing can change how the print looks. You need to follow steps carefully to save money and keep control. Picking the right material is important. Sublimation makes the dye part of the fabric, not just on top. This helps your prints last through daily use.

Callout: Match your dye, fabric, and printing method for the best results.

You want to get the best results from your digital printing. Cost and value play a big role in your decision. You need to look at more than just the price tag. Think about how much you get for your money. High-quality disperse dyes give you bright colors, strong prints, and long-lasting results. You save money when your prints stay vibrant after many washes.

When you compare disperse dyes, check these points:

Color Strength: Strong dyes mean you use less ink for the same effect. You save on ink costs.

Fastness: Dyes with high wash and light fastness keep prints looking new. You do not need to reprint often.

Transfer Efficiency: Good dyes transfer almost all color from paper to fabric. You waste less ink and get better results.

Printer Compatibility: Dyes that work well with your printer help you avoid maintenance costs and downtime.

Versatility: Dyes that fit many applications let you use one product for different jobs.

Here is a table to help you compare cost and value:

Factor | How It Adds Value | Cost Impact |

|---|---|---|

Color Strength | Less ink needed for bright prints | Lower ink expenses |

Fastness | Prints last longer | Fewer reprints |

Transfer Efficiency | More color moves to fabric | Less waste |

Printer Compatibility | Smooth operation, less downtime | Lower maintenance |

Versatility | Use for many projects | Higher overall value |

Tip: You can save money by choosing dyes with high transfer efficiency and fastness. These dyes help you avoid extra costs from reprinting or wasted ink.

TIANKUN CHEM’s Skyinktex® Disperse Dyes offer strong color, high fastness, and reliable performance. You get vibrant prints that last. You can use these dyes for sportswear, banners, and fashion fabrics. The dyes work well with many digital printers. You get consistent results and save on ink and maintenance.

You should also think about the total cost of ownership. This includes the price of the dye, the amount of ink you use, and how often you need to reprint. High-quality dyes may cost more upfront, but they help you save money in the long run. You get better prints, less waste, and fewer problems.

Callout: Choose disperse dyes that give you the best value for your needs. Look at performance, durability, and compatibility—not just price.

You can make smart choices by comparing these factors. You get the best results and save money over time.

You need to pick the right dye for your printing job. First, get your fabric ready. Make sure it is clean and has no extra chemicals. This helps the dye go into the fabric evenly. Here are some easy steps for picking and using dye:

Wash the fabric to get rid of dirt and chemicals.

Mix the dye in warm water, then add it to the main bath.

Put the fabric in and slowly heat it to 85–95°C (185–203°F). Keep the fabric moving gently for 30–60 minutes.

Cool the fabric, rinse it well, and use a gentle fixative if you need to before drying.

If you use blended fabrics, try a two-bath method. Dye the polyester part first, then use acid dye for the nylon. Sometimes, you have to focus on one fiber and accept that the other may not look as bright. For color on the surface, you can use pigment coating or printing.

Tip: Always test how well the fabric soaks up the dye before you start.

Your printer must work with dye sublimation for good results. Dye sublimation inks turn into gas when heated and stick to polyester. You need a printer made for dye sublimation. Check these things before you print:

Make sure your printer is for dye sublimation.

Pick the right print width and duty cycle for your work.

Use the right ICC profiles and RIP settings for good color.

Sublimation transfer printing puts dye on special paper. Then, heat moves the design to polyester fabric. This way, you get clear and sharp prints. Always check that your printer and fabric are right for this process.

Quality checks help your prints stay bright and even. Follow these tips to make sure your prints look good:

Use a good heat press to stop ghosting and uneven color.

Pick the right settings for both paper and fabric.

Keep your workspace at a steady temperature and humidity.

Store your inks and transfer papers the right way.

Use the correct ICC profiles and RIP settings for true colors.

Some common problems are fabric handling, ink stability, fixing the dye, and getting the fabric ready. The table below shows how to fix these problems:

Challenge | Solution |

|---|---|

Fabric handling | Learn what your fabric and ink need |

Ink stability | Pick good inks and take care of your printer |

Fixation methods | Choose the right way to fix dye for your fabric and use |

Pretreatment and washing | Get the fabric ready and wash it right for strong color |

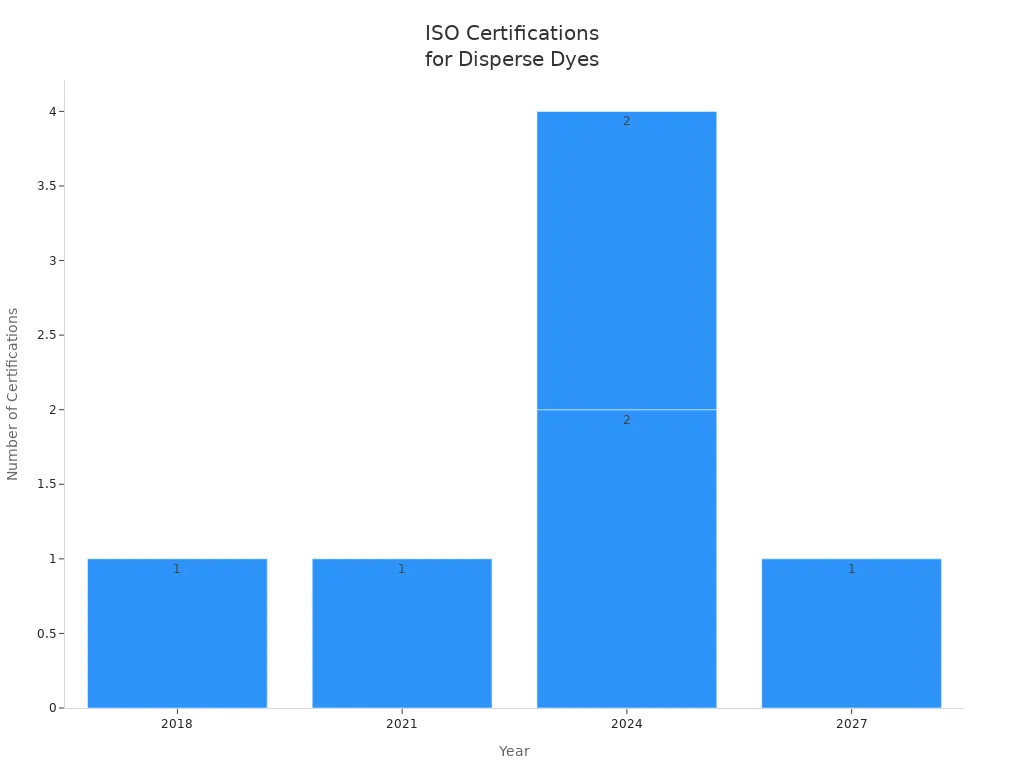

Industry rules help you make sure your prints are safe and high quality. Look for standards like ISO 9001, ISO 14001, and OEKO-TEX. The chart below shows how many ISO certifications there are each year:

Note: Certifications like OEKO-TEX Standard 100, GOTS, and REACH show your dyes are safe for people and the environment.

You want your digital prints to look their best. TIANKUN CHEM gives you many good reasons to use their disperse dyes for sublimation. You can count on their products for bright colors, strong prints, and steady results.

Here are the main reasons to pick TIANKUN CHEM:

High Color Strength: Your prints look bright and bold. Skyinktex® Disperse Dyes make colors pop on polyester fabric.

Excellent Fastness: Your designs stay sharp after washing, sunlight, or rubbing. The dyes do not fade, so your prints look new longer.

Wide Compatibility: You can use these dyes with many digital printers. They work well in inkjet and sublimation machines. You do not have to worry about clogging.

Versatile Applications: You can print on sportswear, banners, flags, and fashion fabrics. These dyes fit many projects and help you meet customer needs.

Eco-Friendly Solutions: TIANKUN CHEM cares about the planet. The dyes transfer well, so there is less waste. Some products have certifications like OEKO-TEX.

Trusted Support: You get help from a skilled team. TIANKUN CHEM gives you advice and support for your printing jobs.

Tip: You can ask TIANKUN CHEM for help picking the right dye for your printer and fabric. Their experts can help you fix printing problems.

Comparison Table: TIANKUN CHEM vs. Other Brands

Feature | TIANKUN CHEM Skyinktex® | Other Brands |

|---|---|---|

Color Vibrancy | Excellent | Good to Excellent |

Fastness Properties | Superior | Moderate to Superior |

Printer Compatibility | Wide Range | Limited to Some |

Environmental Impact | Eco-Friendly | Varies |

Technical Support | Dedicated Team | Varies |

You can see TIANKUN CHEM does better in many ways. You get steady results and good value for your money.

Key Benefits:

You save money because your prints last longer.

You help the environment by making less waste.

You get steady results for every project.

Note: TIANKUN CHEM has helped customers all over the world since 1999. You can trust their experience and focus on quality.

You can visit TIANKUN CHEM’s official website to learn more about their products. You can also check out Skyinktex® Disperse Dyes for Sublimation Inks for more details.

You make a smart choice when you pick TIANKUN CHEM for digital printing. You get bright colors, long-lasting prints, and expert help every step of the way.

You can find brands like TIANKUN CHEM and Skyinktex® Disperse Dyes For Sublimation Inks. These dyes make colors bright and help prints last longer. The table below lists top products and their review scores:

Product Name | Company Name | Review Score |

|---|---|---|

Solvent Red 161 Disperse Dyes | COLORANTS CHEM PRIVATE LIMITED | 5.0 |

Skyinktex® Disperse Dyes | TIANKUN CHEM | 5.0 |

Customized Lowprice Color Masterbatch Disperse Dyes | Jinan Ogilvy Chemical Co., Ltd. | 5.0 |

You need to pick the right dye for your project. Make sure your printer works with the dye. Try to choose dyes that are good for the environment. Always test a sample before you start. Ask your supplier for advice to get the best results.

You use disperse dyes to print bright and lasting colors on polyester fabrics. These dyes help your designs stay sharp and vibrant after washing and exposure to sunlight.

Check your printer model and ink type. Look for dyes with small particle sizes and stable ink formulas. Ask your supplier for advice if you feel unsure.

Yes, Skyinktex® Disperse Dyes offer high transfer efficiency and use safer ingredients. You can find products with certifications like OEKO-TEX, which show they meet strict safety standards.

You get the best results on polyester. Blended fabrics may work, but colors might not look as bright or last as long. Always test a sample before starting your project.

Use dyes with high wash and light fastness. Follow the correct heat and printing settings. Store your prints away from direct sunlight to keep colors looking fresh.

You can choose from many colors, including Blue 56, Fluo. Red 364, Fluo. Yellow 82, Brown 27, Orange 25, and more. These options help you match your design needs.

content is empty!