Dyestuff industry experts

ITMA AISA 2024

- Home

- About

- Online Q & A

- Products

- Applications

- Solution

- Service

- Our Brand

- Info

- Contact

Views: 20 Author: Emily Publish Time: 2025-03-10 Origin: Site

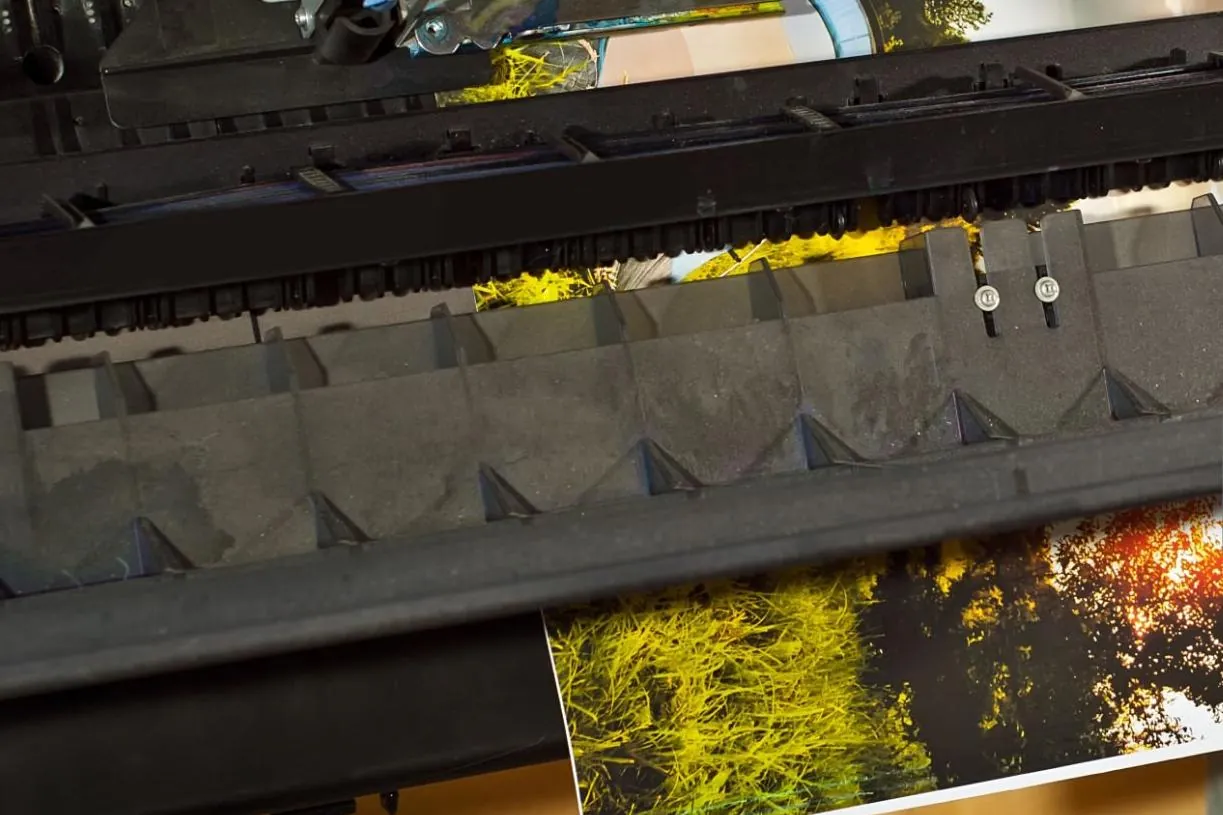

Disperse dyes play a crucial role in the ink industry, offering unique properties that make them highly suitable for various printing applications. Their excellent solubility and dispersion in organic solvents allow for smooth, uniform ink formulations, ensuring high-quality prints with vibrant colors and superior durability.

The primary disperse dyes used in ink formulations include:

Disperse Blue 359

Disperse Blue 360

Disperse Red 60

Disperse Yellow 54

Disperse Brown 27

These dyes are known for their excellent sublimation fastness, making them ideal for applications requiring high-temperature stability. Additionally, since they are derived from crude sources, they contain fewer impurities, leading to improved purity and performance in ink systems.

Vibrant and Intense ColorsDisperse dyes provide a wide range of bright and vivid hues, enhancing the visual appeal of printed materials. This makes them particularly valuable for applications such as packaging, labels, and promotional materials.

Good Lightfastness and Fade ResistancePrints created with disperse dyes maintain their color integrity over time, even when exposed to light, heat, and environmental factors.

Excellent Sublimation FastnessThe selected disperse dyes exhibit superior resistance to sublimation, ensuring that printed designs remain intact and do not degrade during heat-intensive processes.

High Purity and Low Impurity LevelsSince these dyes are sourced in crude form with minimal impurities, they offer greater stability and consistency in ink formulations, reducing potential quality issues.

Enhanced Print Resolution and Color ReproducibilityThe fine dispersion of these dyes allows for precise ink deposition on substrates, leading to sharper, more detailed prints. Their consistent color performance ensures accurate reproduction in commercial and industrial printing applications.

While disperse dyes provide significant advantages in ink formulations, certain factors must be considered:

Compatibility with Different Ink Bases and Substrates: Ink formulations must be carefully adjusted to ensure optimal adhesion and performance on various surfaces.

Proper Handling and Storage: To maintain their stability and effectiveness, disperse dyes should be stored under controlled conditions, avoiding exposure to excessive moisture or temperature fluctuations.

Disperse dyes, particularly Disperse Blue 359, Disperse Blue 360, Disperse Red 60, Disperse Yellow 54, and Disperse Brown 27, are essential components in high-quality ink formulations. Their excellent sublimation fastness, high purity, and vibrant color properties make them a preferred choice for achieving durable and visually striking prints. As technology advances, the continued development of disperse dyes will further enhance ink performance, meeting the evolving demands of the printing industry.