Dyestuff industry experts

ITMA AISA 2024

- Home

- About

- Online Q & A

- Products

- Applications

- Solution

- Service

- Our Brand

- Info

- Contact

Views: 29 Author: Site Editor Publish Time: 2025-12-10 Origin: Site

Preface: Reduction cleaning of polyester generally involves two processes: one is reduction cleaning under alkaline conditions, and the other is reduction cleaning under acidic conditions. In actual production, both processes are used, and the results vary depending on the dye structure and the type of fabric.

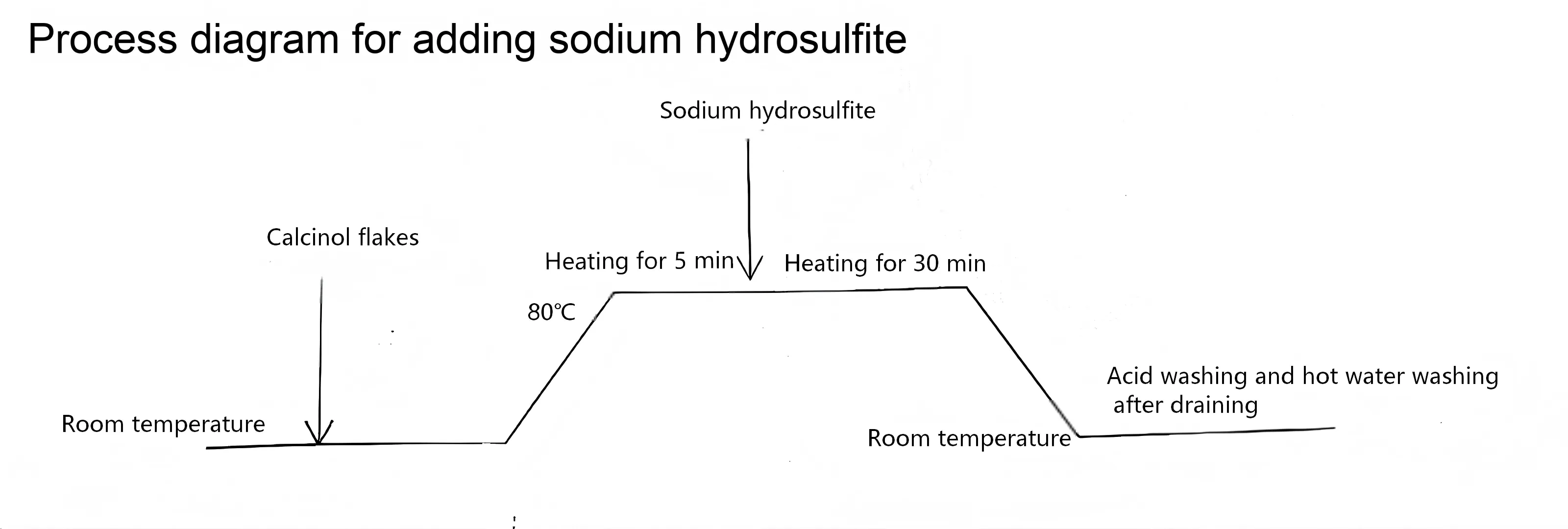

The procedure under alkaline conditions is typically: soaping agent + reducing agent (sodium hydrosulfite or thiourea dioxide) + alkali (caustic soda or soda ash). However, many dyeing plants in China often omit the soaping agent to control costs or due to established process habits.

The soaping agent's function is obvious: it helps dissolve floating dye, disperses dyes more effectively, and reduces re-staining. The multi-functional soaping agent Sylic D2701 has excellent removal effects on various dyes and impurities on dyed and printed fabrics. It also has good chelating ability and is highly acidic, therefore requiring no neutralization.

Sodium hydrosulfite is a commonly used reducing agent. However, compared to Sylic D2740 (CY-315), it is inferior in terms of odor, dosage, and persistence. D2740 can achieve no residual liquor or no water washing in light and medium color processes, and its ability to prevent spandex staining is superior to sodium hydrosulfite. It does not weaken the fluorescence intensity of fluorescent dyes, has higher product stability, and a milder odor.

A typical problem with using sodium hydrosulfite in overflow dyeing machines is that the reducing cleaning solution is easily consumed by oxygen when it encounters air during the spray circulation, resulting in a significant waste. Flat-width washing equipment, however, can save a considerable amount. Some foreign manufacturers have tested using nitrogen to pre-emptively remove air from the overflow machine, and the amount of sodium hydrosulfite used has indeed decreased significantly.

The basic components of reduction cleaning under acidic conditions are the same three: soaping agent, reducing agent, and acid.

A significant advantage of reduction cleaning under acidic conditions is that it can be performed directly after the dyeing process has been completed and cooled to 80–90℃, without the need for draining the dye bath, saving time and water. Additionally, compared to sodium hydrosulfite, the reducing agent in an acidic system is less easily oxidized by air, resulting in more stable dosage.

However, acidic reduction cleaning is not a panacea. In fact, if the dye has an azo structure, the cleaning effect of the acidic system is quite good. But when encountering anthraquinone disperse dyes, it may not be as thorough as traditional alkaline reduction cleaning. This is why some dyeing plants feel that the results are not as good after switching from alkaline to acidic conditions.

After reduction washing, polyester fabrics are mostly subjected to a high-temperature setting at around 180℃ to achieve dimensional stability. However, this leads to a common problem in the industry: although there is no floating dye on the fabric surface when it comes out of the vat, during high-temperature setting, due to the sublimation properties of disperse dyes, the dye inside the fibers will migrate back to the fabric surface.

As a result, the wash fastness often drops by 0.5–1 grade, making it difficult to achieve the 4-grade staining fastness required by many customers.

To address the above issues, Tiankun Chemical has developed a new product:

SKYCRON BLACK GKXF2 300%, exhibiting excellent fastness stability on all-polyester fabrics.

SKYCRON BLACK SWF-KSN Black 300% also demonstrates excellent fastness stability on polyester-spandex, polyester-viscose blends, and polyester-cotton blends.

Comparison data of various high-wash black dyes from Skycron

Dyeing > Reduction Washing → Direct 180℃ Setting After Dyeing, it still achieves excellent performance with staining fastness grade 4 and water fastness grade 4.

This can be considered a truly high-wash fastness disperse black that is unaffected by high-temperature setting.

If you encounter similar problems that you cannot resolve, please contact us at info@tiankunchemical.com