Dyestuff industry experts

ITMA AISA 2024

- Home

- About

- Online Q & A

- Products

- Applications

- Solution

- Service

- Our Brand

- Info

- Contact

Views: 10 Author: Site Editor Publish Time: 2025-10-31 Origin: Site

CD-type cationic dyes can dye acrylic fibers at 100°C and CDP (cationic dyeable modified polyester) at 125-130°C.

However, these dyes are relatively prone to color stains and uneven coloring.

Let's discuss how to avoid these problems.

During the dyeing and chemical preparation process of CD-type cationic dyes, special attention should be paid to the following key issues to ensure dyeing quality, process stability, and safety:

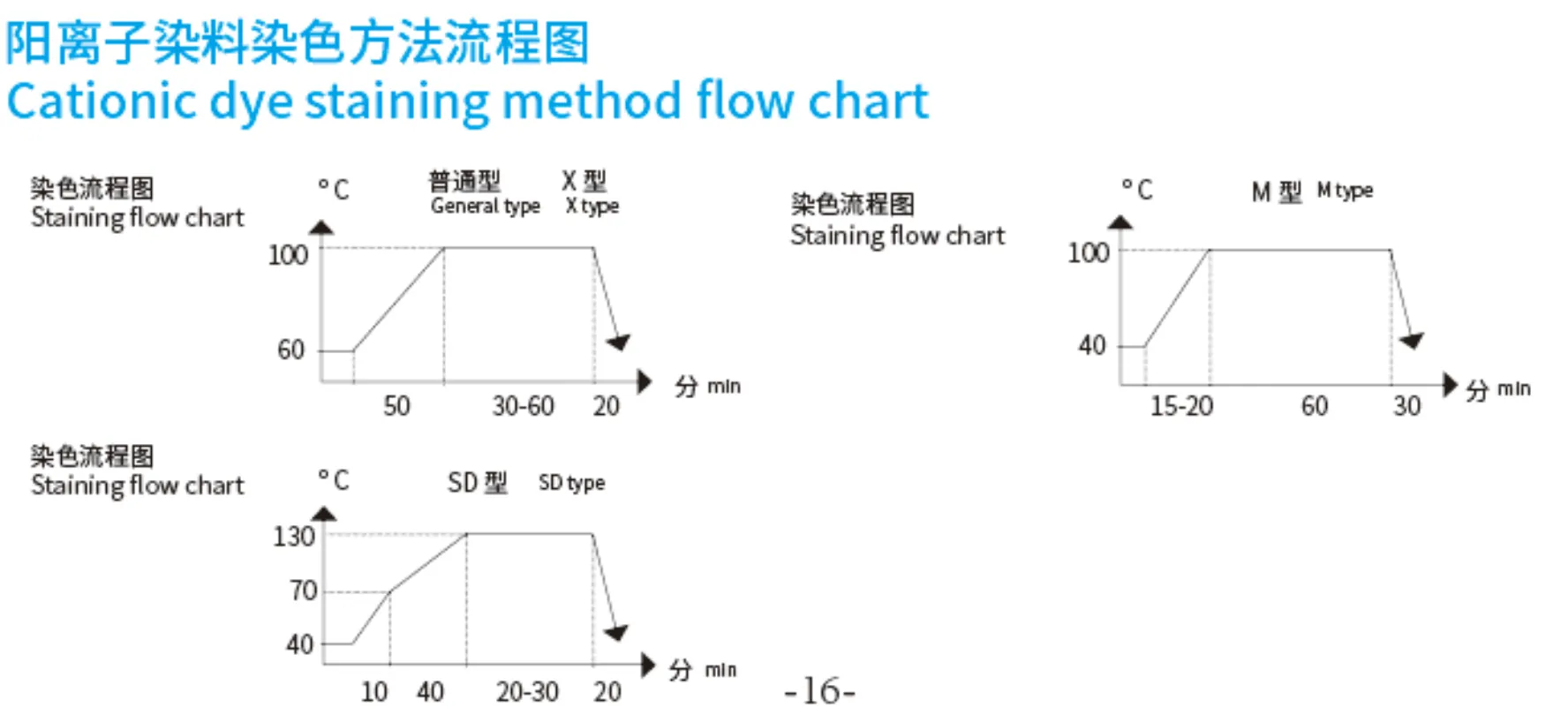

· Cationic dyes are sensitive to temperature and require staged heating (e.g., starting dyeing at 60°C → slowly increasing to 85-100°C).

· Boiling time should not be too long to avoid fiber damage or dye decomposition (acrylic fibers may turn yellow).

· Cooling should be slow (e.g., 1-2°C/min) to prevent uneven fiber shrinkage due to sudden cooling.

* The dyeing bath needs to maintain a slightly acidic environment (pH 4-5), commonly adjusted with acetic acid.

* Too high a pH (>6) may cause dye aggregation or excessively rapid dyeing, resulting in uneven coloring; too low a pH (<3) may damage the fibers.

* A retarding agent such as sodium sulfate (Na₂SO₄) needs to be added to slow down the dyeing rate through competitive adsorption, avoiding uneven dyeing.

* The electrolyte concentration needs to be adjusted according to the dye concentration (generally 1-5% o.w.f).

* Control the bath ratio (usually 1:15-1:30); a too low ratio can easily lead to color differences.

* Add a cationic leveling agent (such as surfactant 1227) to improve migration.

· First, mix a small amount of acetic acid (or warm water) to form a paste, then gradually add hot water (≤60℃) while stirring to dissolve. Avoid direct high temperature to prevent dye coagulation.

· If dissolution is incomplete, filter (e.g., using a 200-mesh filter) to prevent dye particles from remaining in the solution.

· Dye preparation order: Add leveling agent first → acetic acid → dissolved dye → sodium sulfate.

· Avoid direct contact between dye and cationic auxiliaries (may cause precipitation).

· Dye solutions should be prepared and used immediately after preparation. Long-term storage may cause dye hydrolysis or precipitation (especially in high-temperature environments).

· When color matching, select dyes with similar compatibility values (K values) to ensure synchronous dyeing and avoid color deviation.

· Compatibility can be evaluated through dyeing rate curve testing. 2. Dyeing Depth Control

* CD type dyes have strong dyeing depth, requiring precise dosage control (excessive dosage can lead to floating dye, affecting color fastness).

* For dark-colored dyeing, it is recommended to add dye in stages or extend the heating time.

* Acrylic fibers require thorough pretreatment (to remove spinning oil) to avoid affecting dye adsorption.

* Batch variations in fibers may cause color differences; trial dyeing is necessary for confirmation.

* After dyeing, thorough soaping (neutral detergent, 60-70℃) is required to remove floating dye and improve color fastness.

* If necessary, cationic fixing agents can be used (for fabrics requiring high wet fastness).

* Wastewater containing cationic dyes must undergo flocculation sedimentation + oxidation treatment (such as ozone or Fenton process) to avoid direct discharge.

• Ensure COD and color indicators meet standards.

• Wear masks and gloves during dyeing to prevent inhalation of dye dust or skin contact (some cationic dyes are irritating).

• Color variation/color difference: Check heating rate, pH stability, and liquor ratio uniformity; add leveling agent to remedy the problem.

• Insufficient color fastness: Optimize the soaping process or use a fixing agent for post-treatment.

• Dye spots: Check if the dye dissolution is complete and if the dye liquor is filtered.

By controlling these points, the dyeing reproducibility of CD-type cationic dyes can be effectively improved, ensuring stable product quality while also ensuring production safety and environmental compliance. In practical applications, process parameters need to be adjusted according to the specific fiber type (e.g., modified polyester, acrylic).